The logistics and warehousing industry is experiencing a transformative shift driven by cutting-edge technologies. From automation and robotics to artificial intelligence and sustainable solutions, the sector is rapidly adopting innovations that enhance efficiency, reduce costs, and meet the growing demand for faster delivery. Let’s explore the most groundbreaking advancements and the challenges that accompany this evolution.

Robotics and Automation: Revolutionizing Warehouses

One of the most significant trends in logistics and warehousing is the rise of robotics and automation. Companies are increasingly relying on automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) to streamline warehouse operations, from picking and packing to sorting and inventory management. Amazon, for example, has been a leader in deploying robots across its fulfillment centers, reducing human labor while increasing speed and accuracy.

Moreover, automated storage and retrieval systems (ASRS) are becoming the backbone of modern warehouses. These systems reduce human error, improve space utilization, and enable round-the-clock operations. However, there are challenges related to cost of implementation and the need for skilled labor to manage and maintain these systems.

Artificial Intelligence and Machine Learning: Optimizing the Supply Chain

Artificial intelligence (AI) and machine learning (ML) are increasingly being integrated into logistics and supply chain management to predict demand, optimize routes, and reduce operational inefficiencies. AI-powered software analyzes large data sets to forecast trends and make real-time decisions, helping companies to minimize delays and respond to changes in supply or demand.

For instance, predictive analytics is helping businesses optimize their inventory levels, ensuring that warehouses are neither overstocked nor understocked. This balance is critical in reducing holding costs while still meeting customer expectations for quick deliveries. The challenge with AI, however, is ensuring data accuracy and the need for robust cybersecurity measures to protect sensitive supply chain data.

Drones and Autonomous Vehicles: The Future of Delivery

Drones and autonomous vehicles are quickly emerging as the next frontier in logistics. These technologies offer the potential to revolutionize last-mile delivery, significantly reducing delivery times and cutting down on emissions by avoiding traffic and optimizing routes. Companies like Wing (owned by Alphabet) and Zipline have already launched drone delivery services, and autonomous delivery robots are being tested for urban deliveries.

However, regulatory challenges and infrastructure readiness continue to pose significant hurdles. Governments must establish clear regulations for drone airspace and safety protocols for autonomous vehicles, while companies need to invest in charging infrastructure and maintenance systems to support these technologies at scale.

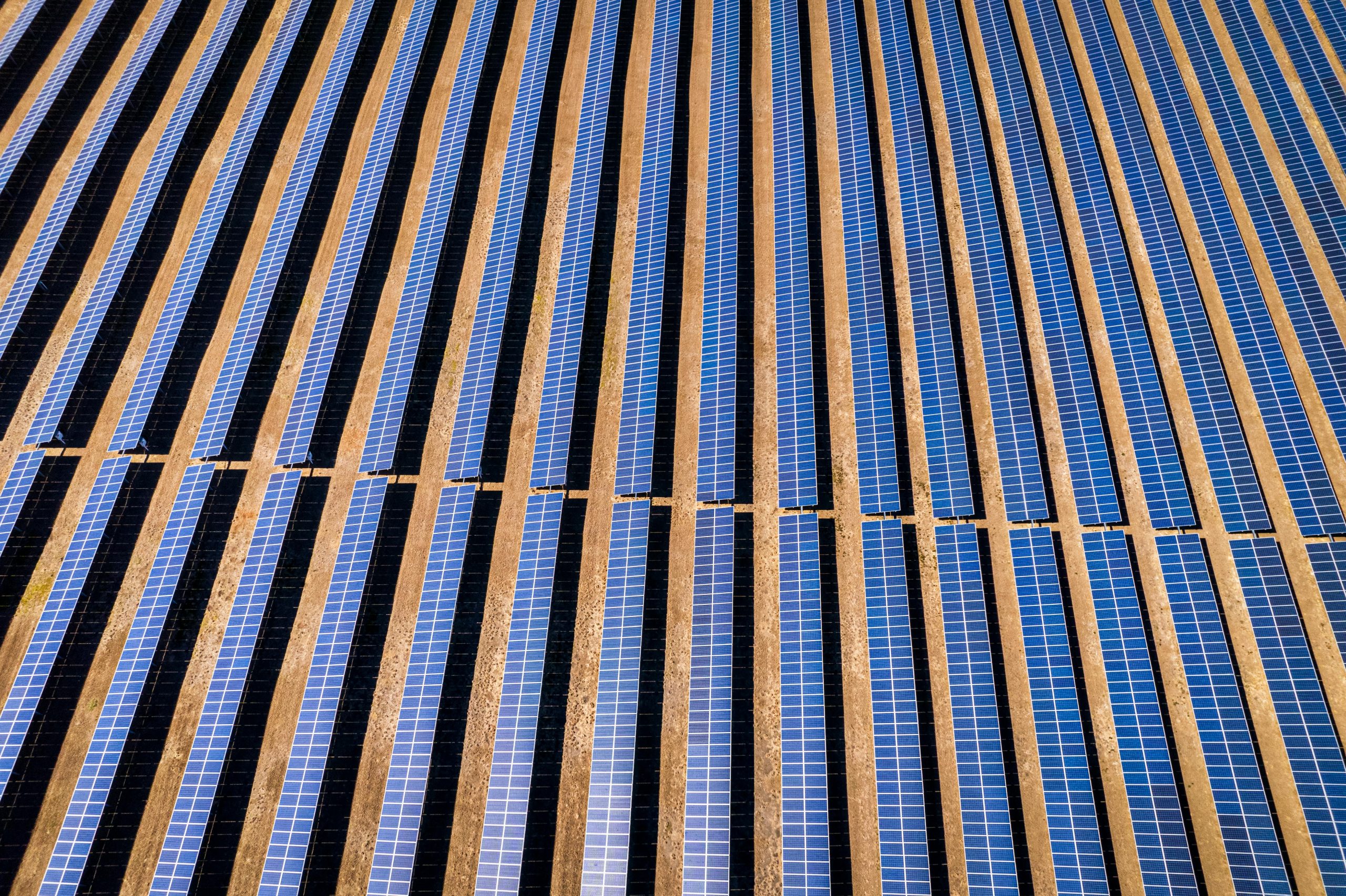

Sustainability: Greening the Supply Chain

Sustainability is increasingly becoming a priority in logistics, with companies seeking to reduce their carbon footprint and optimize energy use. Electric delivery trucks and e-cargo bikes are being rolled out to reduce emissions in the last mile, while solar-powered warehouses and green building materials are gaining traction in new warehouse construction.

In addition to electrification, circular supply chains—where resources are reused or recycled—are becoming a major focus. Many logistics companies are adopting zero-waste initiatives by utilizing recycled packaging and improving reverse logistics for returned goods. The challenge, however, lies in balancing the cost of sustainability initiatives with maintaining profitability, particularly for smaller players in the industry.

Blockchain: Enhancing Transparency and Security

Blockchain technology is making its mark on the logistics industry by providing greater transparency, security, and traceability throughout the supply chain. Blockchain allows all parties involved—from suppliers to customers—to have a secure, immutable record of transactions and goods movement. This not only reduces fraud but also improves the efficiency of contract management and customs clearance.

Despite its potential, blockchain adoption has been slow due to the complexity of implementation and the need for widespread collaboration across the supply chain. Establishing industry-wide standards and ensuring compatibility between systems are critical steps that need to be addressed for blockchain to become a mainstream solution.

Challenges in Access to Resources and Talent

While these technologies offer promising advancements, they also come with challenges. The demand for skilled labor to operate and manage these advanced systems is high, and the shortage of trained professionals is slowing the adoption of automation in some areas. Additionally, access to critical raw materials like rare earth elements, necessary for producing advanced robotics and battery-powered vehicles, is a growing concern.

The logistics and warehousing sector is also grappling with the high cost of implementing new technologies, especially for smaller companies that lack the capital of industry giants. Ensuring that the benefits of these innovations are accessible to all players in the supply chain remains a significant hurdle.

The Path Forward

The future of logistics and warehousing is being reshaped by technologies that promise to improve efficiency, reduce costs, and enhance sustainability. From robotics and AI to drones and blockchain, the potential for innovation is vast. However, the sector must overcome challenges around cost, regulation, and resource access to fully realize the benefits of these advancements.

As technology continues to evolve, the logistics and warehousing industry will play a crucial role in meeting the growing demands of the global economy while transitioning toward a more sustainable and efficient future.